Our Epoxy Flooring Installation Process

A proven step-by-step approach for durable, long-lasting results

Floor Preparation

Proper surface preparation is the foundation of every successful epoxy floor. We use professional diamond grinding equipment to remove contaminants and create a strong mechanical bond between the concrete and coating system.

✔ Diamond grinding for maximum adhesion

✔ Removal of oil, dirt, and old coatings

✔ Concrete repair and crack filling

Grout Coat/Base Coat

The Grout coat seals the concrete and the base coat ensures proper adhesion between layers. This step helps prevent moisture issues, improves durability, and creates a smooth foundation for the final coating system.

✔ Strong adhesion layer

✔ Moisture resistance

✔ Uniform surface for top coatings

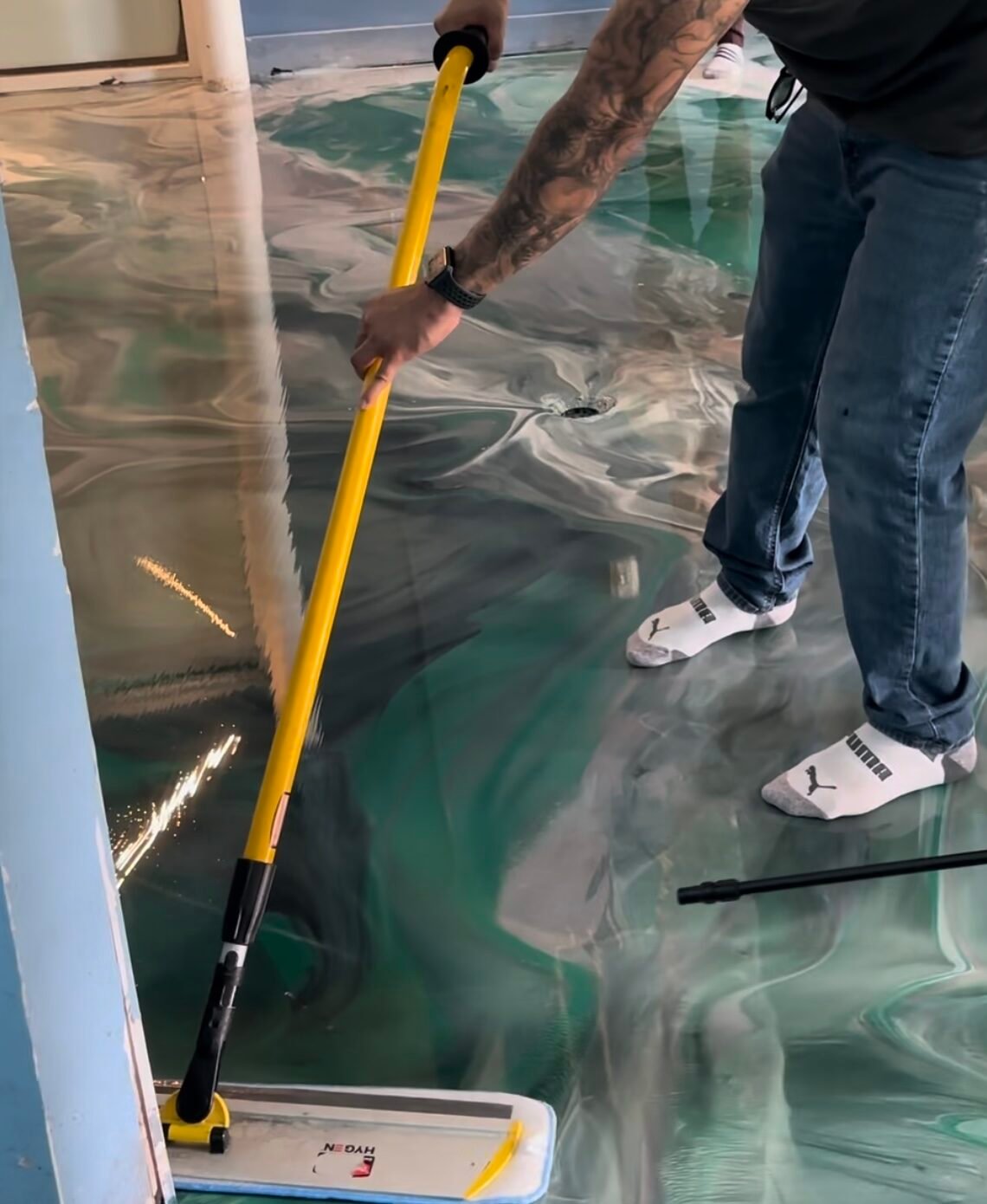

Decorative Coating Application

Depending on your selected system, we apply either metallic epoxy or a flake broadcast coating to achieve the desired look and performance.

✔ Custom metallic designs or flake distribution

✔ Seamless, professional finish

✔ Tailored to residential or commercial use

Protective Topcoat

A durable clear topcoat is applied to protect the floor from wear, chemicals, and UV exposure while enhancing the finish and longevity of the system.

✔ Chemical and abrasion resistance

✔ UV stability

✔ Easy maintenance